Hydraulic cylinders convert fluid power into mechanical force through Pascal’s principle. Pressurized fluid acts equally across piston surfaces. This generates linear motion. The conversion process achieves high efficiency rates. Many systems exceed 90 percent efficiency by minimizing energy losses during pressure-to-force transformation. Hydraulics relies on incompressible fluid characteristics. Force transmits instantaneously across sealed chambers. Cylinder design optimizes conversion through precise machining, effective sealing, and direct mechanical coupling between fluid pressure and load movement.

Sealed chamber design

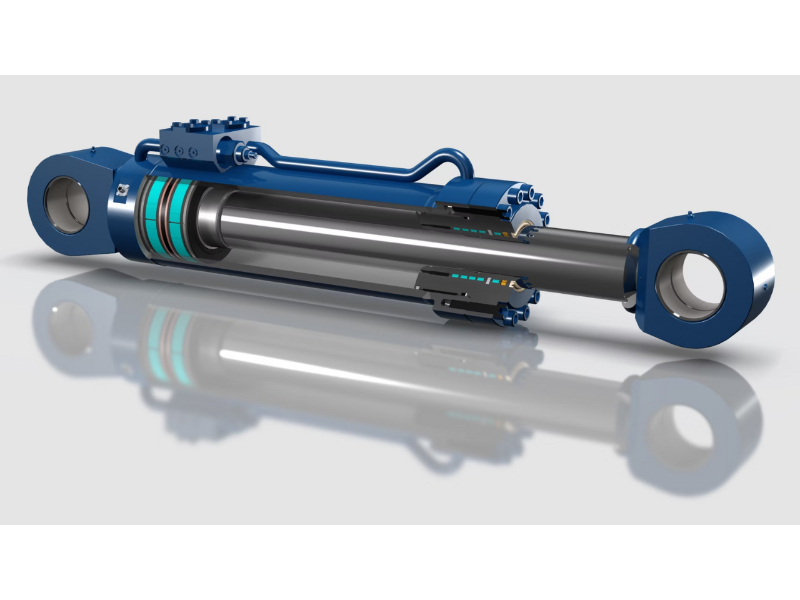

Cylinder efficiency depends heavily on maintaining sealed chambers. Fluid leakage past pistons and rod seals must be prevented. Leakage represents direct energy loss. Pressurized fluid escapes without performing useful work. Modern sealing systems use multiple components working together in precisely machined grooves. Primary seals block fluid passage between high and low pressure areas. Wiper seals remove contaminants from rod surfaces during retraction. Dirt particles damage seals if allowed to enter the cylinder. Wear rings center rods within barrels. This prevents metal-to-metal contact that scores surfaces. Buffer seals provide backup protection when primary seals wear over time. Each element keeps pressurised fluid on the correct side of the pistons, where it generates useful work.

Mechanical force multiplication

- A five-horsepower motor driving a small pump can power a cylinder producing fifty tons of force

- Pressure remains constant throughout the system, allowing one pump to feed multiple cylinders simultaneously

- Force output scales with piston diameter while pump size stays unchanged

- Remote cylinders hundreds of feet from pumps receive identical pressure and generate full-rated force

Minimal energy loss

Well-designed cylinders minimize friction between moving parts. Proper lubrication helps. Precision machining matters. Appropriate clearances are essential. Friction converts useful hydraulic energy into waste heat. That heat requires dissipation, or it damages seals. Tight manufacturing tolerances keep pistons centred within barrels. This reduces metal-to-metal contact that generates friction. Hydraulic fluid itself lubricates sliding surfaces. It flows past seals and around pistons constantly. Smooth cylinder bores reduce resistance during piston travel. Rough surfaces create drag. Chrome-plated rods create hard, slippery surfaces. They minimize friction while resisting wear from repeated stroking cycles. Surface finishes get measured in microinches. Rod coatings must remain smooth enough for seals to glide across without excessive drag. Even minor surface imperfections catch on seal lips.

Direct linear motion

Cylinders convert rotary pump motion into linear output. No intermediate mechanisms like gears or linkages are needed. Those would introduce additional friction points and energy losses. Fluid pressure pushes pistons directly along straight paths. No conversion through rotating components occurs between the pressurised fluid and the linear output force. This direct conversion eliminates complexity. It also removes the efficiency losses inherent in mechanical transmissions. Gearboxes waste energy through friction between meshing teeth. Each gear interface loses a few percentage points of efficiency. Linkages introduce angular deflection and lateral movement. The rod extends and retracts in pure linear motion. Force gets delivered precisely where needed. No deflection occurs.

Hydraulic cylinders convert fluid power efficiently through several interconnected mechanisms. Uniform pressure distribution across piston surfaces provides the foundation. Sealed chambers prevent leakage that would waste pressurized fluid. Mechanical force multiplication allows small pumps to power large cylinders through pressure transmission. Minimal friction losses result from precision machining and constant fluid lubrication. Direct linear motion output eliminates intermediate conversion mechanisms that would introduce losses.